Tea Bag Cut Spices: Precision Ingredients for Consistent Infusion.

As the global demand for herbal teas, wellness infusions, and functional beverages continues to rise, the quality, format, and performance of ingredients have become just as important as their origin. Among these ingredients, Tea Bag Cut (TBC) spices have emerged as a critical category—specially processed to deliver optimal infusion, consistency, and efficiency in tea bags and filter-based brewing systems.

In modern food, beverage, and wellness applications, Tea Bag Cut spices play a vital role in ensuring uniform flavor release, clean infusion without sediment, and smooth processing performance. Unlike powders or irregular cuts, TBC spices are precisely sized to balance surface area and flow, making them ideal for automated tea bag filling, sachets, and ready-to-brew blends.

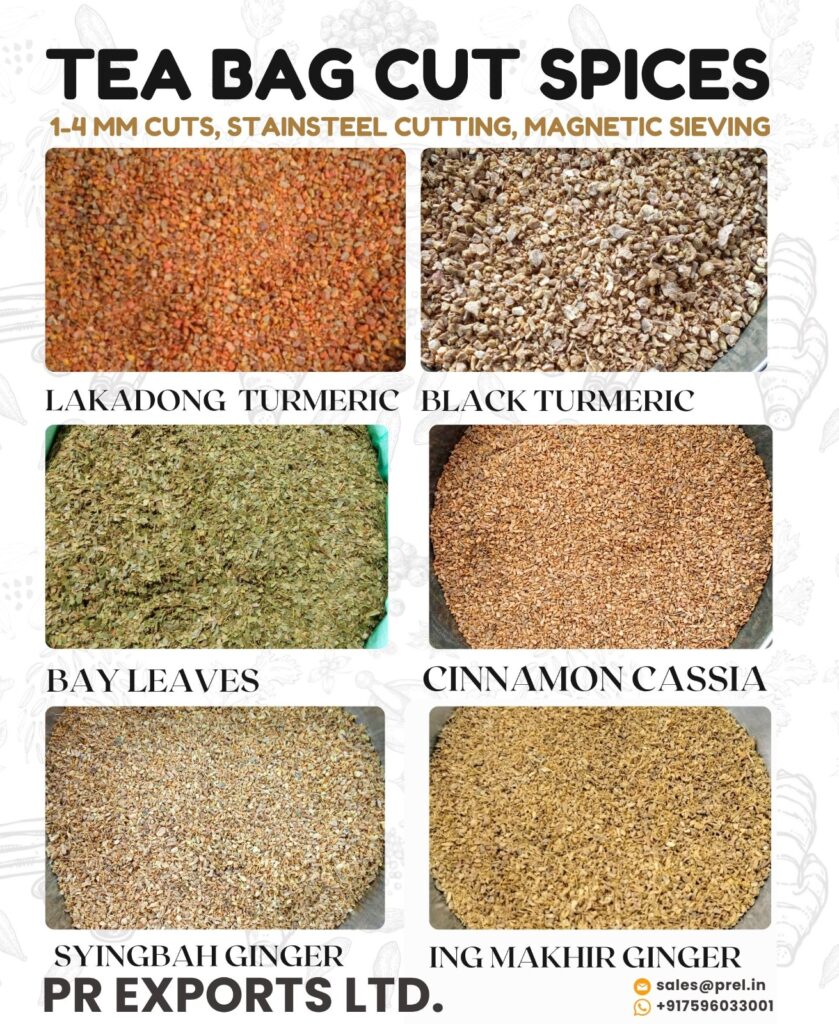

At PR Exports Ltd., we specialize in premium 1–4 mm Tea Bag Cut spices, produced through advanced stainless steel cutting systems and magnetic sieving technology. This controlled process ensures particle size uniformity, metal safety, and high product purity, meeting the expectations of both industrial buyers and quality-conscious consumer brands.

This article explores what tea bag cut spices are, why they matter, how they are processed, and where they are used, highlighting their growing importance in today’s evolving tea, beverage, and wellness industries.

What Are Tea Bag Cut Spices?

Tea Bag Cut (TBC) spices are uniformly granulated spice particles, typically sized between 1–4 mm, designed specifically for:

- Tea bags & infusion sachets

- Herbal teas & functional beverages

- Ready-to-brew spice blends

- Extract manufacturers & nutraceuticals

This precise cut allows optimal surface area for flavor extraction while preventing powder leakage or sediment.

Why Particle Size Matters in Infusions

The success of any tea or herbal infusion depends heavily on particle uniformity.

Tea bag cut spices provide:

- Consistent infusion strength

- Even extraction of essential oils

- Better water flow through tea bags

- Reduced dust and sediment

- Improved visual appeal of the final brew

Uniform cuts also help automated tea bagging machines operate smoothly, reducing breakage, clogging, and wastage during production.

Our Tea Bag Cut Spice Range

Lakadong Turmeric (Curcuma longa)

- High curcumin content

- Strong natural color & earthy aroma

- Ideal for turmeric teas, immunity blends & wellness infusions

Black Turmeric (Curcuma caesia)

- Rich in bioactive compounds

- Popular in functional & ayurvedic formulations

- Carefully processed to preserve volatile actives

Bay Leaves

- Clean, aromatic leaf cuts

- Free from stems & dust

- Suitable for herbal blends and savory infusions

Cinnamon Cassia

- Warm, sweet-spicy aroma

- Uniform particle size for consistent infusion

- Preferred for chai blends and beverage flavoring

Syingbah Ginger (Meghalaya)

- High pungency & natural oils

- Strong infusion strength

- Sourced from high-altitude regions

Ing Makhir Ginger

- Distinct regional aroma

- Clean, low-fiber cuts

- Ideal for premium ginger teas

Advanced Processing & Quality Control

At PR Exports Ltd., quality begins at sourcing and continues through every processing stage.

Multi-Stage Processing System

- ✔ Raw material cleaning & grading

- ✔ Stainless steel cutting (SS-grade equipment)

- ✔ Magnetic sieving to remove ferrous contamination

- ✔ Controlled particle size (1–4 mm)

- ✔ Air-cleaning to remove dust & light impurities

This ensures clean cuts, uniformity, and food safety compliance.

Quality Parameters We Maintain

- Uniform particle size distribution

- Natural color retention

- High volatile oil content

- Low extraneous matter

- Consistent aroma & infusion strength

Each batch is processed under strict hygiene and traceability protocols.

Applications of Tea Bag Cut Spices

Tea bag cut spices are widely used across multiple segments:

- Herbal and wellness teas

- Functional beverages

- Immunity and digestive blends

- Ayurvedic and traditional formulations

- Detox and cleansing teas

- Ready-to-brew infusion sachets

- HoReCa bulk brewing systems

Their clean cut and consistent performance make them ideal for both retail tea brands and large-scale industrial blenders.

Advantages for Manufacturers and Tea Brands

Using tea bag cut spices offers several operational and commercial benefits:

- Improved batch consistency

- Faster infusion times

- Reduced sediment and dust

- Lower production waste

- Better consumer experience

- Enhanced shelf presentation

For export-focused brands, standardized cuts also help meet international quality and safety expectations.

Quality, Traceability, and Export Readiness

Reputable suppliers of tea bag cut spices prioritize:

- Source traceability

- Hygienic processing

- Batch uniformity

- Moisture and cleanliness control

- Export-compliant packaging

These factors are critical for buyers supplying markets in Europe, the Middle East, North America, and Asia-Pacific.

Conclusion

Tea Bag Cut spices are more than just ingredients—they are precision components that directly influence flavour release, infusion clarity, and batch-to-batch consistency in herbal and functional beverages. As consumers increasingly demand clean-label, functional, and premium tea experiences, the importance of well-processed, uniformly cut spices has never been greater.

Selecting high-quality Tea Bag Cut spices ensures superior brewing performance, reliable processing efficiency, and consistent sensory results, while also strengthening brand credibility in an increasingly competitive global market. Poorly processed cuts can compromise infusion quality, whereas precision-cut spices enhance both product performance and consumer trust.

At PR Exports Ltd., our 1–4 mm Tea Bag Cut spices are engineered for buyers who demand precision, purity, and performance. Whether you are a global manufacturer, a private-label tea brand, or a health-focused consumer business, our TBC spices deliver clean infusion, consistent quality, and full regulatory confidence—helping you create products that meet modern market expectations with confidence.